In the heart of America’s industrial engine, a quiet revolution is unfolding. Amid rising borrowing costs and lingering global uncertainties, the manufacturing sector has demonstrated an inspiring level of adaptability and strength. From bustling plants in the Midwest to specialized workshops on the coasts, stories of innovation and perseverance highlight how industries are overcoming challenges and laying the groundwork for future prosperity.

As interest rates climbed through 2024 and into 2025, manufacturers braced for higher financing costs and compressed profit margins. Yet, despite these obstacles, output growth has remained steady. A series of PMI readings above the 50 threshold signals continued expansion, defying predictions of a prolonged slowdown. While some investment decisions were delayed or scaled back, companies have found creative refinancing solutions and optimized working capital to maintain momentum.

The surge in input expenses has been especially notable. Driven by supply chain bottlenecks, tariffs, and wage growth, materials and labor costs surged to levels unseen in nearly three years. In April and May 2025, output price inflation hit a 29-month high, presenting a direct threat to manufacturer margins. Still, by leveraging long-term supplier agreements and pursuing leaner operations, many firms have preserved competitiveness in both domestic and international markets.

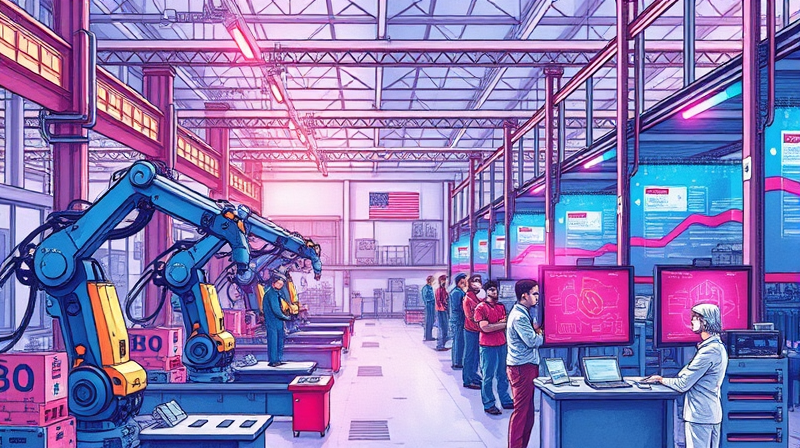

To counteract ongoing volatility, industry leaders are accelerating the integration of emerging technologies. AI-driven analytics, robotics, and advanced automation platforms are no longer experimental; they are essential tools for survival and growth. By harnessing data in real time, manufacturers can anticipate disruptions and adjust production schedules, ensuring continuity even amid unexpected shocks.

These initiatives are part of a broader commitment to build a resilient manufacturing ecosystem amid uncertainty. By reshoring key processes and diversifying supplier networks, companies reduce exposure to geopolitical risks and strengthen domestic capacity.

Contrary to expectations of mass layoffs under financial stress, the manufacturing workforce has remained largely intact. With approximately 13 million employees as of April 2025, the sector has seen only minor job fluctuations. Hiring, quits, and openings have all trended downward, reflecting a more stable employment environment where workers and employers value continuity and skill retention.

Small and medium-sized manufacturers (SMMs) play a pivotal role in this landscape. Representing 98% of all firms and employing nearly 4.8 million workers, these businesses have embraced workforce development programs and upskilling initiatives. Partners with community colleges and training providers, many SMMs offer apprenticeships in advanced manufacturing technologies, ensuring their teams stay competitive in an era of rapid change.

Through targeted training and mentorship, these firms are forging a more inclusive workforce culture and reducing turnover costs, further underpinning sector resilience.

Federal and state policies have been instrumental in sustaining industry growth. Incentives for reshoring, tax credits for R&D, and grants for workforce development have collectively generated a fertile environment for private investment. In late 2024, more than seventy-five percent of surveyed manufacturers planned to increase spending on digital technologies and supply chain fortification.

Looking ahead, public-private partnerships are set to expand, targeting strategic areas such as semiconductor production and critical materials processing. These efforts align with a common recognition: sustained private and policy investment is essential to secure America’s competitive edge in a rapidly evolving global economy.

Despite the headwinds of higher rates, inflationary pressures, and global uncertainties, the US manufacturing sector continues to demonstrate remarkable durability. Across boardrooms and shop floors, leaders are uniting around a shared vision: advancing innovation while safeguarding supply chain integrity. By embracing technology, nurturing human capital, and leveraging supportive policies, the industry is not merely surviving—it is charting a path toward strong domestic demand underpinning growth and long-term prosperity.

The journey forward will demand agility, collaboration, and unwavering commitment. Yet, the narratives emerging from plants nationwide offer reason for optimism. In every automated assembly line and every skilled operator’s workshop, we see the promise of American industry—resilient, adaptive, and forever evolving.

References